Although Dr Bécaye Diop grew up in a city in Senegal, where he studied biology and chemistry, it is the village that gave him purpose. He was surprised when he visited his mother’s village as a child to see that unlike in the cities, villagers did not have toilets in their houses. “It was a shock for me because I came from the city. So, when I went to the university, I learned that we could have some solutions for this kind of situation,” he said. Most villagers dug pit latrines. Later, Diop also realised most people in urban areas in Senegal were not connected to the main sewer, which benefits from treatment. The majority relied on on-site sanitation, where a septic pit is dug to serve many people. On-site sanitation is the easiest way to meet sanitation needs because it is cheaper. However, studies have shown that if implemented without the right precautions, pit latrines and on-site sewers can contaminate groundwater. After university, Diop founded a company that specialises in the treatment of faecal sludge.

The company further pioneered an innovation that valorizes the sludge to produce usable by-products. Solarization is the process of heating the waste without any oxygen. This process kills any pathogens and produces liquid fuel and compost that is sold as organic fertiliser to vegetable farmers. “What we are trying to solve is the pollution of nature, the pollution of groundwater, the contamination of surface water and the healthcare situation. Leaking waste and faecal sludge can cause many problems to the environment and public health,” Diop said. He added, “At the same time we try to contribute to climate change mitigation by creating new products such as compost.” Through the valorisation process, they can guarantee 100 per cent pathogen elimination, which ensures a pathogen-free fertiliser. “Our solution is contributing to the resilience against climate change.

We are producing raw materials coming daily from households. We do not need to import [fertiliser] from other countries. Also, we produce fuel locally,” he said. “We protect the climate by reducing the use of fuel from fossils.” The company operates ten faecal sludge treatment plants in Senegal, Diop’s home country, and three faecal treatment plants in neighbouring Benin. Each plant employs people living within the locality. Diop always wanted to be an entrepreneur. He says his mind was always clear that he would start his own company and not look for a job.

He says local production of fertiliser boosts farm produce and reduces carbon emissions associated with buying food produced miles away. “The world is one village, and we have vegetables coming from all the countries. We need to use fuel through planes, boats, or vehicles to transport products but if we have local production, we reduce greenhouse gas emissions and contribute to the fight against climate change. That is for me a way for people in developing countries to contribute to the solutions in fighting climate change,” he says. Diop notes at least 80 percent of people in Africa use onsite sanitation, which means volarization potential is high, creating a circular economy. The business is based on a public-private partnership model where the company also offers advisory services to governments and businesses on how to operate faecal sludge treatment plants. He says the main challenge is that many sewage plants in Africa are not designed for valorization and therefore require extra work if the sludge is to be treated. Last year, Diop’s company applied for the Adaptation and Resilience ClimAccelerator in Africa.

This programme, initiated by the climate innovation organisation EIT Climate-KIC, is an African-wide accelerator project for start-ups to innovate, catalyse and scale the potential of their climate solutions. The programme, implemented by KCIC Consulting Limited (KCL) and Concree SAS, offers those firms access to funding, expertise, and mentorship. Funded by the Department of Foreign Affairs and Trade of Ireland (Irish Aid), the Adaptation & Resilience ClimAccelerator supported 16 start-ups from across the African continent with solutions that address physical climate risks or build the resilience of communities in early 2023. The selected start-ups received tailored business coaching, professional guidance on finance, support defining the climate impact potential of their solution, and preparation for future investment opportunities. “This programme is really supporting us to better understand our markets. And to have the right strategy to penetrate it more easily,” said Diop. “It is very important for us because we are not really the sellers of these byproducts we are producing.

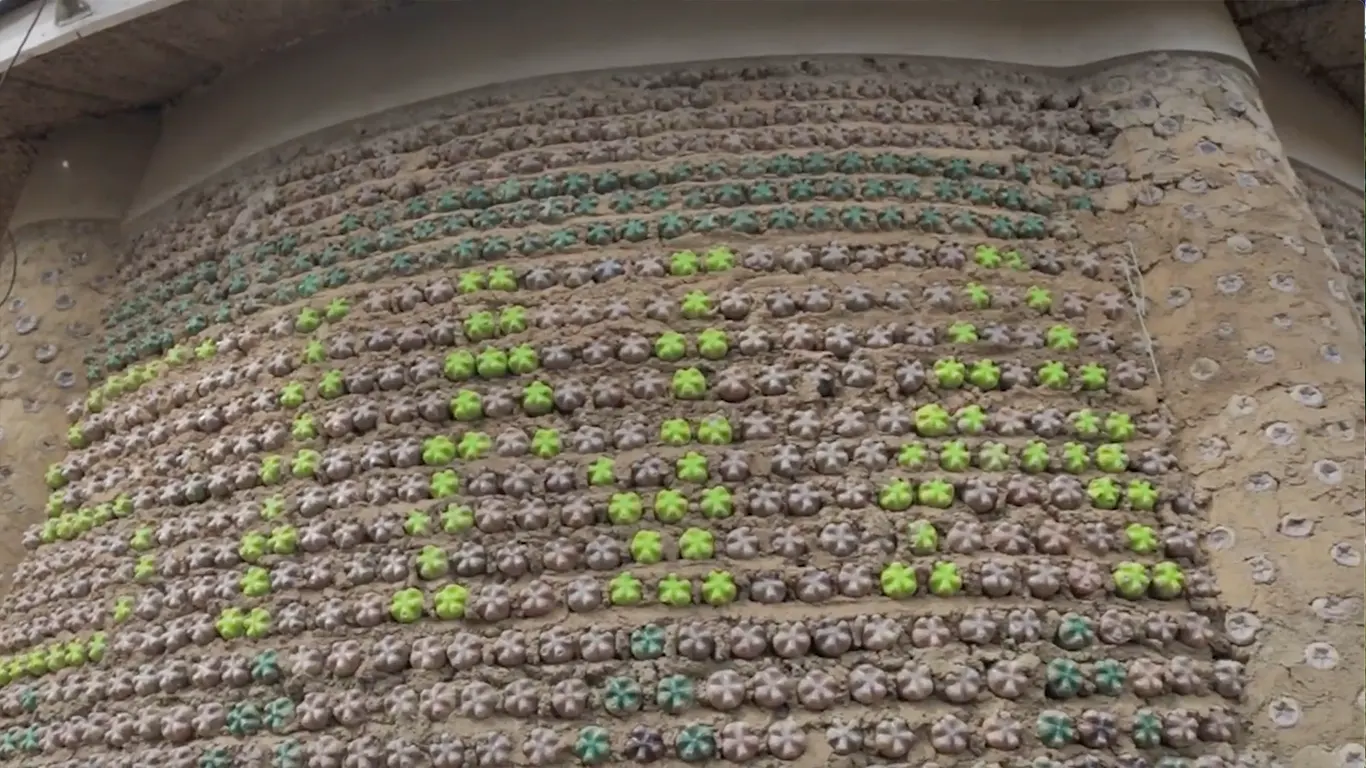

We specialise in how to treat the sludge and how to valorize it to produce good quality products. Which begs the question, how do we sell them, how can we ensure they are available in the market? This requires additional expertise and specialization in marketing which is far different from our technical proficiency” He said the incubation programme helped them identify the right partner company to sell the byproducts. “We hope to increase our customers, and market share in order to grow better and faster.” Following the mentorship, the quality of the company’s byproducts was certified by Senegal’s National Institute for Research in Agriculture (ISRA). “The results were very great. We produce a very high-quality compost certified by ISRA and also the vegetables we produce from this compost are better quality compared to those produced using chemicals,” Diop said.

He said going forward, the company needs support from the government and other partners to redesign existing sewage treatment plants to be able to valorize the sludge. The certification by the National Institute for Research in Agriculture will also be extremely important going forward. “Now the challenge is to extend this experience and for that, we call upon additional partners to provide additional support to the one given through this project,” he said.